You don’t need a Stanford MBA to effectively manage restaurant food costs. However, what you do need, is military-like discipline paired with exceptional organizational abilities. Fortunately, operators can acquire these traits over time through a little structure and repetition. By mastering these basic inventory management skills and recruiting some help from your team members, you will be rewarded with the consistency and accuracy you’ll need to become a Food Cost Ninja!

Why Food Cost Management Is Important

Inventory is the equivalent of your restaurants’ DNA, and it’s the best way to get an accurate representation of what your true usage is. Inventory is the point where all essential restaurant management begins. Your inventory should be a total of all the food product, nonalcoholic beverage, beer, wine, liquor, (Note: For QSRs we suggest including your packaging in this as well), etc. If done properly, performing inventory enables you to better manage general restaurant volatilities such as Food Costs and Labor Costs, Gross Profit, Repair and Maintenance, and also your Cash Flow.

3 Fundamentals of Restaurant Inventory Management

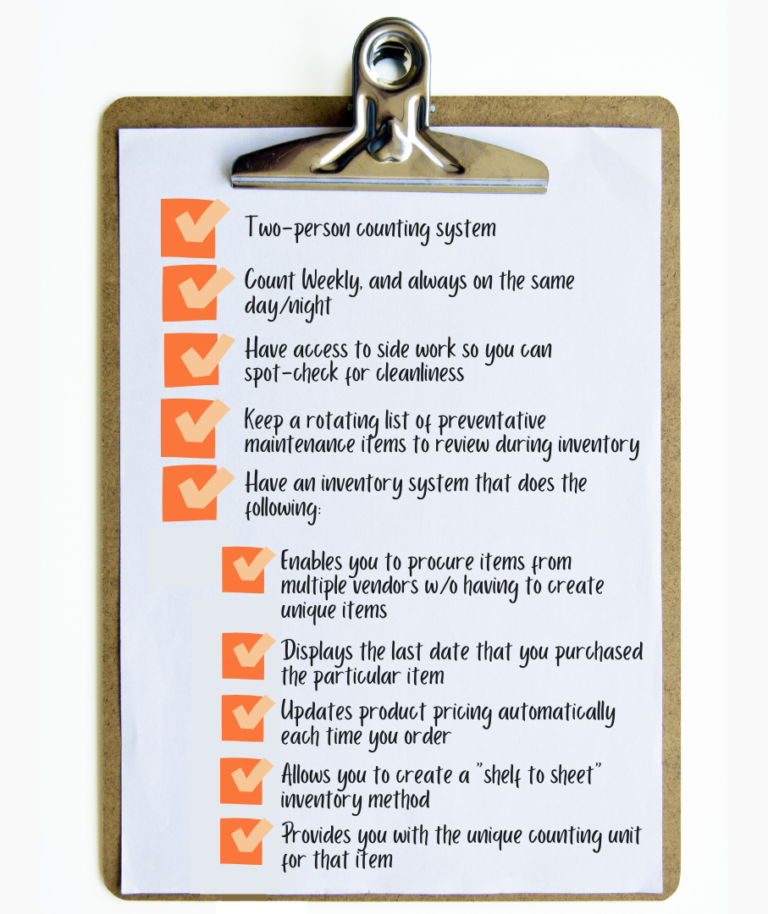

Fundamental #1: Utilize a Two-Person Inventory System

When it comes to inventory, don’t go at it alone. The average restaurant has over 475 items in the BOH (Back of the House) alone. Combined with the bar, we’re looking at 800-900 items that need to be counted.

Performing a Two-Person Inventory is a required fundamental. One person calls the product, while the second person writes it down. The benefits of performing a two-person inventory are as follows:

- Having an extra person in the process ensures accuracy & consistency within your results

- A two-person inventory allows each team member to focus on the task at hand

- By going through this process every single time you count your inventory, you begin to develop a rhythm

- You now have a Plan B when one of your team members moves on to another career

- Ask any coach… you always want depth within the players on your team, and inventory is like playing a position on a team

- The more you master your own position as well as get to be familiar and versatile with other positions, the more helpful you are to your team as a whole

Fundamental # 2: Inventory Isn’t Just About Counting

There’s much more to taking inventory than simply counting bottles and food products. Taking inventory enables operators to focus on keeping an eye on these key factors:

- Verification of Side Work

- Every restaurant has assigned side work. When not checked regularly, 80% of the side work assigned is completed poorly or not completed at all

- Performing a weekly, two-person inventory enables team members to also focus on the cleanliness of the restaurant that results from consistent side work

- A good rule of thumb is to have your side work built into your count sheets so that you can cross-reference it (or even grade it) when you’re moving through the inventory process

- Reduction of Repair & Maintenance

- Repair and Maintenance, or R&M, is like the Boogeyman under your bed. Except in your restaurant, the Boogeyman is everywhere. He’s the PVC under your dishwasher that has cracked, the HVAC System with the clogged intake vents, the compressor in the beer cooler, the O-rings around the cooler doors, the iced-up freezer, the burned-out light bulbs, wobbly tables, or the leaking toilet in the bathroom

- Each week, keep a rotating list of “big ticket” items that are critical to the success of your restaurant

- Perform a mini preventative maintenance check (PMC) on these items during your inventory

- The time spent doing a PMC will save you thousands of dollars

Fundamental #3: Your Product is an Investment

If your walk-in, liquor storage, and beer coolers were bank vaults they would have round wheels and Fort Knox-like security. The point here is that we normally keep our cash in a bank. In our restaurants, however, we keep our cash in the form of products, and as stated earlier, there are about 800-900 of them.

If your walk-in, liquor storage, and beer coolers were bank vaults they would have round wheels and Fort Knox-like security. The point here is that we normally keep our cash in a bank. In our restaurants, however, we keep our cash in the form of products, and as stated earlier, there are about 800-900 of them.

When added up each week products can tie up $15,000- $150,000 of our cash flow. Treat your product as an investment. Inventory and proper restaurant purchasing are the 2 best ways of increasing your cash flow.

Best Ways to Manage COGS (Cost of Goods)

Here are the best ways to keep a watchful eye on your investment in order to manage your COGS and increase your cash flow. As a quick refresher and reminder, our Cost of Goods is calculated with the COGS Formula below:

COGS = BEGINNING INVENTORY + PURCHASES – ENDING INVENTORY

- Know the Value of your Inventory:

- Just like stocks, inventory value fluctuates because items such as Produce, Dairy, Meat, and Seafood are commodities. The prices on these items can change weekly. Items such as Wine can be purchased at multiple price points due to allocations and varietals. Make sure that your inventory prices are updated before each time you take inventory.

- If your prices have changed and you are calculating your inventory based on outdated pricing, the accuracy is completely null. You’ll have a meaningless value and have no chance of knowing whether you’re paying too much for the same products and using up too much cash relative to your sales.

- Monitor the Deliveries

- There is a direct relationship with performing weekly inventory and effectively purchasing for your business. Inventory frequency helps manage product rotation, product rotation helps manage waste, and waste helps manage purchasing frenzy. Proper ordering starts with proper inventory management.

The Anatomy of a Good Restaurant Inventory Management System

Get in Touch with RASI

Contact us today for any of your restaurant inventory, costing, and cash management needs!